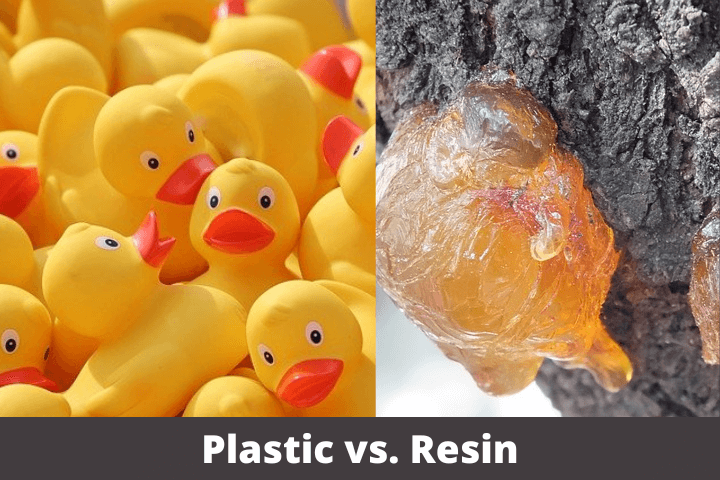

A major difference between plastic and resin lies in their origin. Resins have a natural origin as they are derived from plants. Plastics, on the other hand, have synthetic polymeric nature and are obtained from petrochemicals. That is the reason, plastics are sometimes called synthetic resins.

Plastic vs Resin

| Plastics | Resins |

| Plastics are synthetic polymers and are obtained from petrochemicals | Resins are organic hydrocarbons that are obtained directly from plants and thus, have a natural origin |

| They are highly stable | They are less stable |

| Plastic materials can be remelted (moulded) easily | Resin materials are hard to remelt (mould) |

| Plastics are more durable than resins | Resins are less durable than plastics |

| Plastic materials are made free from impurities | Resins cannot avoid impurities |

| They are hard and dense | They are gluey and viscous |

| Materials made up of plastic are difficult to repair | Materials made from resins are easy to repair |

| Plastic substances give an unnatural impression | Resin substances give natural and more original feelings |

| Plastic is the final product, however, can be used further | Resin is referred to as unprocessed plastic |

| Plastic materials do not degrade easily. They also have toxic characteristic additives. Thus, they are not environment friendly | Resins being natural products do not have any adverse effects on the environment. Thus, they do not add to polluting our earth |

| Examples of plastics are Polyethylene terephthalate (PET), Polyvinyl chloride (PVC), Polypropylene (PP), Low & High-Density polyethylene (LDPE, HDPE), Polystyrene (PS), etc | Examples of resins are amber, balsam, Boswellia, copal, and balm of Gilead, etc |

Additional Resources

What is Resin?

Resin is a group of semi-solid or sometimes solid amorphous compounds. It is obtained from plants directly such as from plant exudations. Most of the resins are clear yellowish-brown in color. They mainly consist of terpenes and some non-volatile solids. Bicyclic terpenes are the most common terpenes found in resins.

Resins have been used for many years. They have a wide range of applications. Some of the common applications include sealing boats and food containers. They also serve as a major component in many organic products such as varnish, jewelry, perfumes, inks, etc.

New and advanced methods have also been developed by using which the raw natural resin is turned into functional polymers. This is how synthetic resins, plastics, came into being. Synthetic resins are produced under controlled conditions and hence, are important in the industrial sector.

The common examples of resin are balsam, Canada balsam, balm of Gilead, and other trees that belong to the family of Dipterocarpaceae. Resins were considered a prized substance and were given religious importance in history as well.

Resin has a long history since the ancient ages when it was being treated as a prized substance and was given a religious value as well.

Some categories of resins, based on their composition are:

- Nylon (polyamide) resins

- Acetal resins

- Thermosetting (polyester, vinyl ester, epoxy) resins, etc

What is Plastic?

Plastics are generally considered synthetic resins. However, the more suitable way is to call them synthetic or semi-synthetic organic polymers of high molecular masses. Plastic materials are moldable. Being derived from petrochemical, they remain partially natural.

However, there are some plastics that are purely natural and are called bioplastics. Such plastics are produced from renewable plant materials. So, unlike common plastics, bioplastics are not harmful to our environment by being biodegradable.

In order to enhance the required properties in plastics, different organic and inorganic additives are added to them. More often, the color and rigidity of plastics need to be changed. So, the additives play their role here. For example, plasticizers are used to reduce the rigidity of plastic materials, etc.

Some unique properties of plastics are as:

- Hard and dense

- Resistant to heat (to some extent)

- Oxidation

- Have good insulation properties

- Good transparency and wear resistance

- Light-weighted and chemically stable, etc

Note that plastics being typical polymers of hydrocarbons, also contain elements other than hydrogen and carbon, such as oxygen, sulfur, nitrogen, halogens, etc. Some of the examples of plastics are given below:

- Polyethylene terephthalate, commonly known as PET

- Polyvinyl chloride or PVC

- Polypropylene (PP)

- Low-density polyethylene (LDPE)

- High-density polyethylene (HDPE)

- Polystyrene (PS)

Plastics vs Resins: Key TAkeaway(s)

Concepts Berg

What are the similarities between plastics and resins?

- Both resins and plastics are long-chain hydrocarbons.

- Both are polymers because of the presence of repetitive units (monomers).

- They are both lightweight materials.

Are resins eco-friendly?

Yes, most of the resins come from natural sources and thus, are biodegradable. So, they are ecofriendly. Synthetic resins, such as polyresins, polyester resins, and thermosetting resins, are not eco-friendly.

What are the types of resins?

Resins are classified into two types; natural resins and synthetic resins, depending on their source.

Resin vs plastic strength:

Resins can be broken down depending on thickness and curation. However, plastics are very strong and cannot be broken easily. When put to UV rays, the plastic will take about 20 years to decompose.

What is the difference between rubber and plastic?

Rubber is a natural product obtained from rubber trees whereas plastic is a synthetic product, manufactured in industry.

What is the difference between acrylic and plastic?

Acrylics are a form of plastics, but not all plastics are acrylics.

What is better: Resin or Plastic?

Both resin and plastic are important depending on the use. For example, the resins are environment friendly and thus, are encouraged to use. However, plastics also have some important properties such as strength, moldability, reliability, etc.

References

-

Engineering Control Technology Assessment for the Plastics and Resins Industry By Enviro Control, Inc (Rockville, Maryland 20852)